Controllers (Controlled pulse tools)

The Pulsor Focus 4000 controls EPP C tools. With its built-in functions, it also participates in controlling the station or line segment. The Pulsor Focus 4000 and associated software package provide easy-to-understand information for everyone, from operators to plant managers. The Pulsor Focus 4000 is based on standard hardware and software components which, when combined, will fulfill all demands, from the most basic stand-alone installation to full integration into the factory network. The modules fit together using the “plug-and-play” concept. Assembly process control and quality assurance is made easy by advanced control functions. On receipt of assembly information, the Pulsor Focus 4000 automatically selects the correct tightening sequence and parameters. The operator is guided through the process, avoiding mistakes that can result in costly quality problems. Advanced process control and monitoring functions make it easy to view and collect data using the Internet infrastructure.

สอบถามรายละเอียดสินค้า หรือ ขอแคตตาล็อกสินค้า

Further detail of products required, pls feel free to contact us.

- Pulsor Focus 4000-C-PN-HW

- Pulsor Focus 4000-C-PB-HW

- Pulsor Focus 4000-C-IB-HW

- Pulsor Focus 4000-C-EIP-HW

- Pulsor Focus 4000-C-DN-HW

- Pulsor Focus 4000-C-HW

RBU – Hardware key (Controlled pulse tools)

Atlas Copco’s patented Rapid Backup Unit (RBU) concept transfers functionality to a non-configured hardware unit, ensuring that hardware can easily be upgraded should functionality requirements change. The RBU also acts as back-up for programming and configuration. If a change of hardware is required, just fit the RBU to the new hardware, switch on the unit and you’re ready. All programming and network configurations are transferred in seconds. The RBU cuts downtime to a minimum.

Features & Benefits :

• Run Pulsor C tools

• Store up to 100 program settings, maximizing productivity in the station and reducing the need for additional tools

• Count batch, count numbers of bolts to be tightened, to increase error proofing in assembly operations

• Cross thread and rehit detection to increase quality during assembly process

• Tool service indicator to help user plan preventive maintenance, reducing costs on run-to-fail

• Lock tool on reject to reduce operator’s influence on decisions, reducing quality related costs

• Store up to 5,000 (default) tightening status (OK/NOK) for short/mid term traceability

• Store up to 5,000 (default) tightening data for short/mid term traceability

• Real time statistics, including statistical process control (SPC) to monitor the process, detecting deviations sooner

• Click wrench input supported for operation back-up, assuring the assembly process

• Angle control and torque monitoring for better control during tightening process

• RS232 port for programming

• USB port for programming

• Discrete I/O to interface with a production line

• QIF (error proofing modules) connectivity, such as socket selectors, for easy installation in demanding error proofing applications

• Parallel printer port

• Expandable I/O (up to 124 in/124 out)

• Open protocol serial

สอบถามรายละเอียดสินค้า หรือ ขอแคตตาล็อกสินค้า

Further detail of products required, pls feel free to contact us.

Software (Controlled pulse tools)

ToolsTalk Pulsor C W10: Programming Software for Pulsor C system

With Pulsor C programming software you can program the system 100%. There are license options for 1, 5, and 10 users – a plant license is also available.

Features & Benefits :

• Easy to connect and use

• 100% system programming and network set-up

สอบถามรายละเอียดสินค้า หรือ ขอแคตตาล็อกสินค้า

Further detail of products required, pls feel free to contact us.

Tool control box (Controlled pulse tools)

This is the key component of the Pulsor C system. Pressure adjustment and tool shut-off valves are located inside the box.

Features & Benefits :

• Pressure can be adjusted so that one tool can handle multiple torque levels.

• Pressure can be adjusted during the tightening cycle to improve accuracy.

• Two programmable buttons for more advanced operation.

สอบถามรายละเอียดสินค้า หรือ ขอแคตตาล็อกสินค้า

Further detail of products required, pls feel free to contact us.

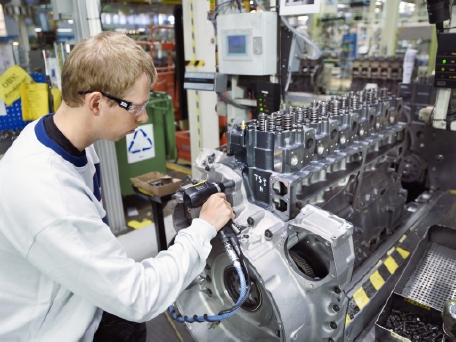

Tools (Controlled Pulse Tools)

Controlled, Pneumatic, Hydraulic Pulse Nutrunner

Atlas Copco’s Pulsor C System gives you all the advantages of a controlled impulse tool, plus the intelligence of an electric fastening system. Like all Atlas Copco pulse tools, Pulsor C is fast, powerful, light and compact and generates virtually no reaction force. The controller remembers up to 4,000 tightenings that can be stored and analyzed. This enables you to fine-tune your process and ensure that every tightening in every shift is perfect.

Features & Benefits :

• No missed screws – Pulsor C counts the tightenings and signals “Batch OK”

• Forget stripped screws – Pulsor C ensures the screw has been tightened correctly

• No wrong/forgotten parts – Pulsor C signals “NOK” if the wrong screw or part is used

• Correct torque every time – Pulsor C controls the torque level

• Good repeatability – get consistent tightening on hard and soft joints

• Premature trigger-release warning – LEDs warn operator of interrupted tightening

• Multiple P-set – one tool can perform up to 100 different P-sets. The right torque setting is selected by exchanging sockets, scanning barcodes and more.

• High-speed tightening – Atlas Copco pulse tools are fast and powerful, helping to boost productivity.

• Easy to set up and use.

• Hot swap – you can change the tool or cable without shutting the system down because the tool shut-off is located in the Tool Control Box instead of the tool. No new settings in the tool are needed.

สอบถามรายละเอียดสินค้า หรือ ขอแคตตาล็อกสินค้า

Further detail of products required, pls feel free to contact us.

- EPP11 C110 HR-B13

- EPP10 C90 HR-B13

- EPP10 C90 HR13